In the world of carpets, a significant evolution is taking place as weaving technology bridges the gap between machine-made and hand-made carpets. With advancements in textile technology, manufacturers are creating machine-made carpets that replicate the intricate craftsmanship and aesthetic appeal of traditional hand-made pieces. This transformation not only enhances product quality but also opens up new avenues for market expansion and consumer choice.

The Journey from Machine-Made to Hand-Made Aesthetics

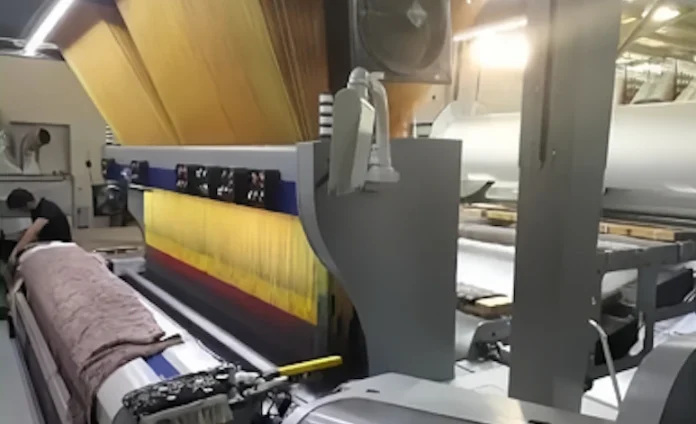

Machine-made carpets have long been celebrated for their efficiency and cost-effectiveness. However, they often lack the unique qualities and artisanal craftsmanship associated with hand-made carpets. The introduction of innovative weaving technologies has revolutionized this perspective, allowing manufacturers to produce carpets that mimic the appearance and feel of hand-woven products.

1. Innovative Techniques: Modern weaving techniques utilize advanced machinery that can replicate complex designs and patterns traditionally crafted by skilled artisans. This includes intricate motifs that draw inspiration from various cultures, including Afghan and Central Asian designs, which appeal to a broader audience seeking authenticity and uniqueness.

2. Finishing Processes: The process of transforming machine-made carpets into hand-made-like products involves several finishing touches. After the initial production, carpets are subjected to washing, shaving, and hand-finishing, which enhances their texture and overall aesthetic. These steps not only improve the quality but also allow for greater customization, giving each carpet a distinctive character.

3. Quality Control: Implementing rigorous quality control measures throughout the production process ensures that the final product meets high standards. This commitment to quality has led to increased consumer confidence and market acceptance of these innovative carpets.

Market Expansion and Consumer Demand

The evolution of weaving technology has not only redefined product offerings but has also catalyzed market expansion. As manufacturers adapt to the changing landscape, several key factors contribute to their success:

1. Export Opportunities: The ability to produce carpets that combine the best of both worlds—machine efficiency and hand-made aesthetics—has positioned manufacturers to tap into international markets. For instance, a notable portion of products is exported to countries like France, the United States, and Germany, reflecting a growing demand for high-quality carpets that blend traditional design with modern production methods.

2.Diverse Collections: New collections, such as those introduced for 2024, showcase a blend of classical and contemporary designs, appealing to a wide range of consumer preferences. By reinterpreting traditional motifs and patterns, manufacturers cater to both nostalgia and modern tastes, thus expanding their market reach.

3. Sustainable Practices: As environmental concerns rise, the textile industry is increasingly focused on sustainable practices. The technology employed in producing machine-made carpets can also incorporate eco-friendly materials and processes, aligning with consumer demand for sustainability.

Future Prospects

Looking ahead, the carpet industry is poised for further innovation and growth. Companies committed to harnessing the power of weaving technology will continue to lead the way in creating products that resonate with consumers seeking both quality and authenticity. As competition in the global market intensifies, manufacturers must remain agile, embracing new technologies and market trends to maintain their competitive edge.

1. Investment in Technology: Continuous investment in advanced weaving technology will be crucial for manufacturers aiming to improve their product offerings. Staying at the forefront of technological advancements will enable companies to create even more intricate designs and patterns, further blurring the lines between machine-made and hand-made carpets.

2. Consumer Education: Educating consumers about the benefits of machine-made carpets that emulate hand-made qualities will be essential. By highlighting the craftsmanship involved in the production process and the quality assurance measures in place, manufacturers can build trust and encourage consumers to consider these products as viable alternatives to traditional hand-made carpets.

3. Collaboration and Innovation: Collaborating with designers and artisans can foster a culture of innovation within the industry. By bringing together different perspectives and expertise, manufacturers can push the boundaries of carpet design and production, resulting in unique products that cater to a diverse audience.

Conclusion

The evolution of weaving technology has ushered in a new era for the carpet industry, transforming machine-made carpets into products that rival their hand-made counterparts. As manufacturers continue to innovate and adapt to market demands, the future looks bright for this sector. With a focus on quality, sustainability, and consumer education, the carpet industry is set to thrive, delivering exceptional products that honor tradition while embracing modernity.